Do you really know how a batch freezer works to create frozen desserts?

For chefs around the world certain kitchen equipment is a necessity even if it’s not fully understood how it operates. Most chefs probably couldn’t tell you how their freezers work or how their immersion circulators keep their accuracy. In the case of ice cream and gelato shops perhaps the most important yet the least understood piece of equipment is the batch freezer.

A Batch Freezer Defined

A batch freezer is a piece of equipment used in the commercial production of frozen desserts such as gelato, sorbetto, ice cream, custard and sherbet. In this particular freezer, the ice cream, gelato, sorbetto, custard or sherbet liquid base is simultaneously frozen and whipped which in return creates the smooth consistency to which we associate frozen desserts with. There are four different categories of batch freezers to select from: regular horizontal, all-in-one combination, open vertical and a multi-purpose machine that goes beyond gelato and ice cream. Somewhere between a home ice cream maker and a commercial continuous freezer, the batch freezer is the perfect option for small business owners. It allows for the production of varying batch sizes. An at-home ice cream maker can only process a very small size of liquid base, whereas a typical batch freezer can process up to 24 quarts. A continuous freezer, as its name suggests, has no limit on its capacity. Another dynamic professional kitchen appliance that many businesses use and are familiar with, it processes a beaker of frozen base and then “shaves” extremely fine layers of the frozen product to produce a creamy, very finely textured frozen dessert.

The question that is asked most about batch freezers is what is the difference between an air- cooled machine and a water-cooled machine. The answer is simple; water-cooled machines circulate tap water around the compressor or condensing unit. An air-cooled machine simply blows air across the condensing unit. Most would think that water-cooled machines are wasteful but in most cases they actually use the smallest amount of water possible to do the job. Air-cooled machines, on the other hand, can fill a small shop’s production area with hot air making the room quite uncomfortable. In this case most business owners will then turn the air-conditioning on resulting in a higher use of electricity. In most cases, whether air-cooled or water-cooled, modern companies design their machinery to have the exact same efficiency no matter what the environmental conditions are, so it is really a personal preference when it comes to choosing one or the other.

How It Works

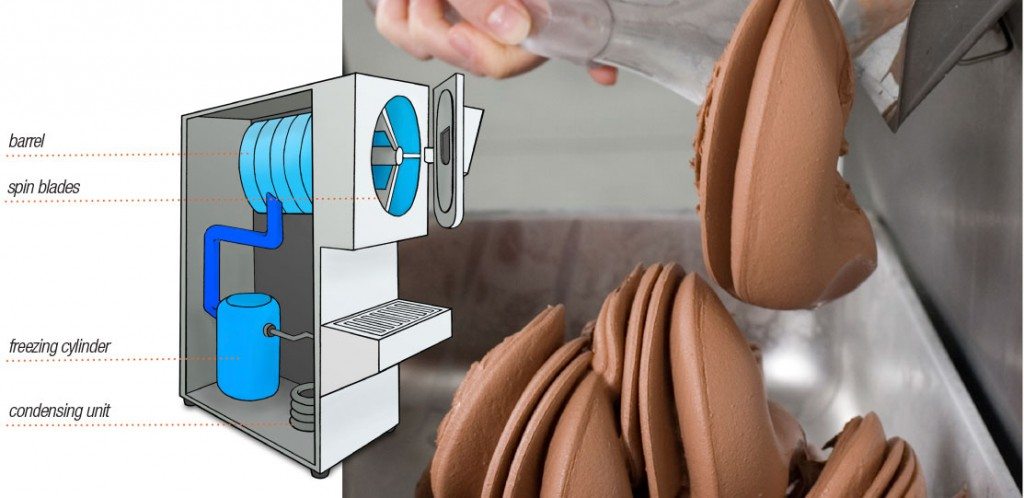

1. A batch freezer, like any other refrigeration device has a condensing unit. This is the engine of the batch freezer. The condensing unit compresses environmentally friendly Freon gas into a cold liquid, and water is then pumped to the freezing cylinder. The liquid base is then placed in a barrel that is surrounded by pipes containing the Freon and water solution, which freezes the barrel from the outside. The barrel itself is generally made from corrosion resistant material or stainless steel.

2. When in operation, the machine spins a blade inside of the barrel at a consistent speed. The spinning of the blade whips the mixture by introducing air bubbles into the base as it freezes, trapping them to create the finished texture. Generally most batch freezers have an overrun between 30%–35%. There are specific models on the market that actually allow the controller to compute how much overrun can be introduced into the mix, but they are considerably more expensive. The faster the blade spins the smaller the air bubbles which produce smaller ice crystals. This is important to remember because the smaller the ice crystals, the smoother the finished texture of the frozen dessert will be.

3. The blade inside of the barrel scrapes the frozen ice crystals off the wall before they become too big. As the blade spins, it creates even-sized ice crystals throughout the base which results in the even freezing of the product. All machines have blades made of a nonreactive material such as a heavy-duty plastic that allows constant direct contact with metal without causing an unwanted chemical reaction that could potentially be a health hazard.

Temperature Control & Systems

The doors are generally made of special thermal insulating materials that help to regulate the internal temperature of the barrel. The freezing cylinder control systems on machines all vary by brand. Some have electronic thermostats with probes that are in direct contact with the mix. These thermoregulators automatically manage all temperature exchanges by rotating between hot and cold gas or reading how many amps are used to regulate freezing consistency.

There are more pros than cons when it comes to batch freezers. Currently there are batch freezers that range in all different sizes from 2 quarts up to 44 quarts. Some models can even mix the base, heat treat and freeze it in a matter of 20 minutes. Churning time is monitored and controlled with accuracy, and newer models can even stop the freezing process as extraction is happening so that as the product comes out it has the same consistency from beginning to end.

If you are planning on buying a batch freezer use our list of questions to help you determine what machine best fits the needs of your business.