A good base is essential in the production of artisanal gelato. With it comes many advantages, such as an extended shelf-life, a consistent level of quality and a well-balanced mix that guarantees the total hygiene of the product. A base also accentuates any added flavoring and simplifies production in an efficient and systematic way.

Most PreGel bases contain sugar, non-fat powdered milk, stabilizers (guar or locust bean gum), emulsifiers (monoglycerides, diglycerides and lecithin, for example) and milk-based flavoring. The percentage of each ingredient in a gelato recipe depends on the base’s composition. It is very common to use 50g, 100g, 150g or 200g of powdered base for every 1,000g of whole milk.

Sugars & Fats

Sugars and fats have major functions in gelato and sorbetto. Sugar adds sweetness and controls the amount of frozen water; while fats provide a creamy texture, a dairy flavor, and contribute to overrun – the amount of air incorporated into a product.

Stabilizers

It is easy to understand how stabilizers work when you compare them to a sponge. Their main function is to absorb as much free water as possible. This prevents the formation of ice crystals during freezing and storage of gelato. Stabilizers combine solids and liquids within the product, creating a smoother texture, giving it a desired resistance to melting, and improving its handling properties. The amount of stabilizers used is typically around 0.2%-0.5%., but varies depending on the solid content of the mix and the type of processing equipment.

Emulsifiers

Emulsifiers are extremely important as they impede the separation of butterfat from water. The result is a product with a dryer, smoother texture and consistency. Essentially, they are the buffer between the water and other solids in your recipe. In addition, they reduce the melting rate of the finished product and produce smaller ice crystals that are more evenly distributed. Many powdered bases today contain both emulsifiers and stabilizers for the obvious advantages they provide. Since they are both used in small quantities (0.5% of the mix), it is nearly impossible to incorporate them into the recipe without compromising the end result of the final product.

Processes

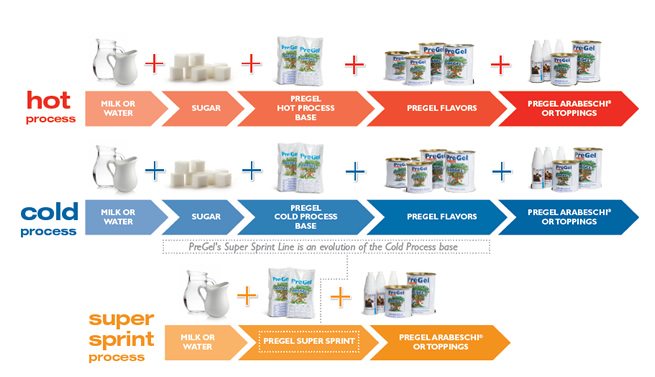

PreGel products include bases that can be used in two different processes – hot and cold. Hot Process requires a pasteurizer that heats the mix to a temperature of 185°F/85°C in order to activate the stabilizers and emulsifiers before cooling them down to 39.2°F/4°C. Flavoring is then added to the base before placing it in a batch freezer. This process takes about an hour to produce approximately 60 liters of base, although it should be noted that the amount varies depending on the type of pasteurizer used. The advantages include greater flexibility and savings due to lower ingredient costs.

Cold Process is a faster approach which requires only one machine. The ingredients used are specially formulated to include stabilizers and emulsifiers that do not need heat for activation. PreGel’s Super Sprints, for example, are instant powders which only require the addition of milk or water. These bases do not require additional flavoring, sugar or cream.

PreGel bases are highly useful for gelato production since they have been specially formulated with technology that helps obtain a well-balanced mixture in terms of sugars, fats and solids. You simply add the liquid and flavor component, and sugar as needed. Therefore, using a base is essential in ensuring a top quality product. PreGel AMERICA offers a wide array of Hot and Cold Process bases that allow for personalization and meet the needs of all businesses.

Milk Bases

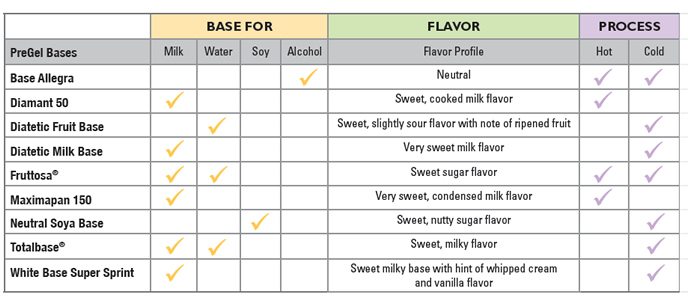

Diamant 50 and Totalbase® require the addition of milk and provide a soft creamy milk base for gelato and ice-cream. Totalbase® can be used with water to create a creamier sorbetto if desired. For a more velvety and airy texture, use Maximapan 150. The Dietetic Milk Base is a sugar-free alternative. PreGel’s Traditional Pastes offer a wide variety of cream flavorings that are added to these bases before placing in a batch freezer.

Fruit Bases

PreGel’s fruit bases are the modern-day solution for fresh sorbetto preparation. Fruttosa® has a neutral, sweet flavor and is easily personalized using PreGel’s Fortefrutto® fruit pastes. The Dietetic Fruit Base is a low-calorie, sugar-free option that only requires the addition of water. Any fresh, frozen or pureed fruit that is added must be of high quality. Special consideration should be given to the natural sugar and water content to maintain the right balance

of ingredients.

Alcohol Bases

Adding alcohol to a frozen dessert should always be done in moderation, as it contains additional sugars which can affect freezing. PreGel’s Base Allegra allows for the production of alcohol-infused gelato and sorbetto that hold up well in the display case, since alcohol-based flavors have the tendency to become soft and break down.

The Right Foundation

Ideally, gelato should posses a pleasant color and taste, a homogeneous smooth texture, and an adequate resistance to melting. The quality of an artisanal gelato is subjective and dependent on one’s ability, expertise and understanding of clients’ expectations. Creating a high-quality frozen dessert involves specific knowledge, and PreGel’s powdered bases are the ideal solution. Not only do they allow for personalization, but they produce the perfect texture by preventing and correcting any defects in the finished product. As with all of life’s endeavors, the successful production of a frozen dessert rests on a good foundation.